Furnace Blackening Technology (FBT)

The proposed Furnace Blackening Technology (FTB) is aimed at improving the efficiency of the fire chambers in furnaceindustrial devices.

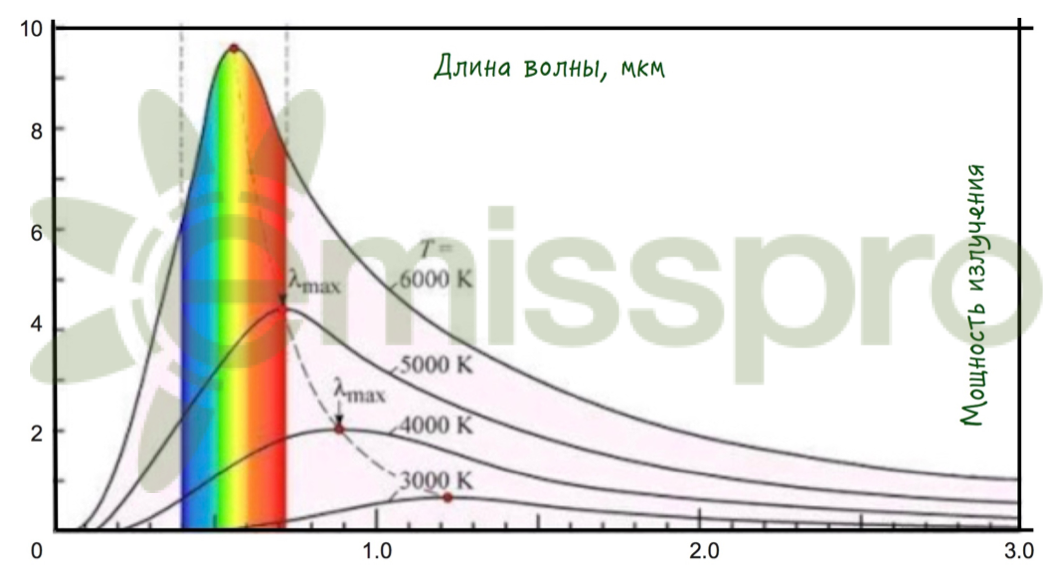

Graph of the dependence of the Radiation Power of a blackbody on the Wavelength of radiation and the Temperature:

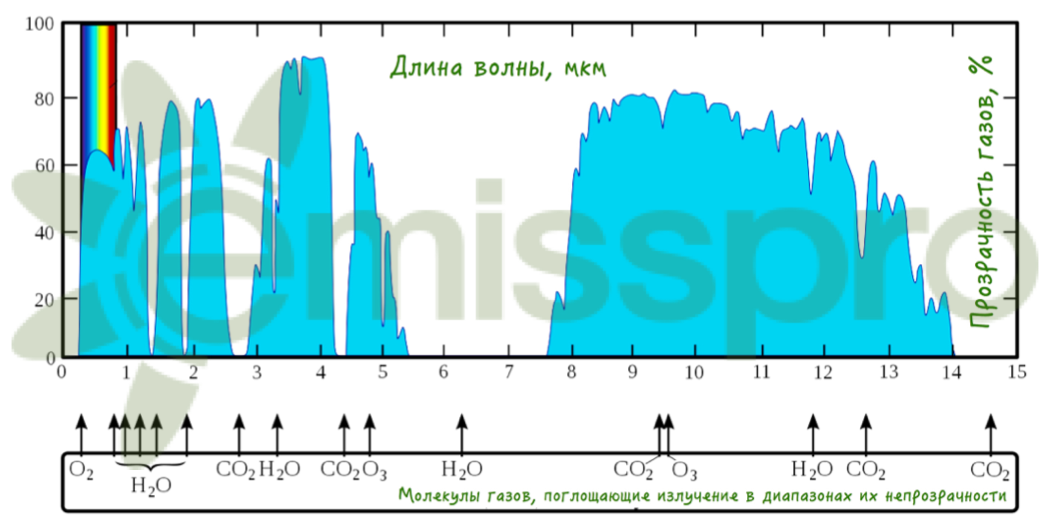

Graph of the Opacity of gases depending on the Wavelength of radiation and Molecules of 3-atomic gases:

Modern oil refining and petrochemical processes Furnaces are designed in such a way that the main heat load is transmitted through radiant heat exchange in the Radiation Chamber of Furnaces. The ratio of thermal load between the Radiation and Convection Sections is 80% to 20%, respectively. Therefore, in terms of energy consumption and energy efficiency of the entire Furnace apparatus, the Radiation Chamber ia given increased attention.

The FB Technology is implemented by combination of three factors of radiant heat exchange in furnace, namely:

- so-called "luminosity" or "blackness" of the torch;

- emission coefficient of the secondary reflector - refractory surface in the combustion chamber of furnace;

- blackness coefficient of heated surfaces - screens or pipes for heating of raw materials.

High-Emissivity Ceramic (HEC) coatings are designed to increase the blackness of the refractory surfaces and heated surfaces in the Radiation Chambers of heating and reaction Furnaces.

At the same time, it is known that the main structural materials used for refractory the radiation chambers of furnaces reduce their own Blckness Coefficient (BC) with increasing temperature. For example, the BC of ceramic fibre material decreases dramatically from 0.75 to 0.45 (by 40%) when the temperature increases from 20 to 1000 degrees Celcius.

Dependence graph of the Blackness Coefficient on Temperature for refractory materials

At the same time, the Coefficient of High-Emissivity Ceramic (HEC) coating does not significantly change its value of 0.92 of higher.

Thus, by applying HEC coatings to the internal surfaces of the Radiation Chamber, it is possible to achieve an increase in the efficiency of transmitting radiant energy due to the consistently High Blackness of the furnace combusttion chamber.

Starting from the first completed work in 2011 to the present Green Ray company employees have done:

- 29 Projects of Furnace Blackening Technology have been successfully implemented at various production sites of PJSC "Gazprom neft", PJSC "Rosneft", PJSC "LUKOIL", PJSC "SIBUR Holding" and others in Russia, Bulgaria and Serbia;

- HEC coatings were successfully applied to 74 Furnaces of varios Refineries, including: JSC "Gazpromneft - Omsk Refinery", JSC "NIS a.d. Novi Sad Refinery" (Serbia), LLC "Gazpromneft - Omsk Lubricants Plant", JSC "LUKOIL Neftochim Burgas" (Bulgaria), LLC "LUKOIL - Nijnii Novgorod Refinery", JSC "TAIF-NK", LLC "TomskNeftechim", JSC "Rosneft - Novokuibyshevsky Refinery", JSC "Rosneft - Ryazan Refining Company", JSC "Slavneft - YANOS";

- Numerous positive reviews and references have been received from our Customers from various Oil Companies, including PJSC "Gazprom neft", PJSC "LUKOIL", PJSC "NIS Gazpron neft" (Serbia). You could find positive reviews on the web-page "Customer Feedback" of this site;

- FB Technology is recognized as the BEST PRACTICE in PJSC "Gazprom neft" and is in the process of such recognition in PJSC "LUKOIL";

- FB Technology with HEC coatings has been successfully applied to heater and reaction furnaces of various technological processes, including: primary refining (AD and VD), hydrotreating and hydrorefining, aromatics production, catalytic remorming, catalytic cracking of VGO, dewaxing and selective cleaning of oils, hydrocarbons isomerization, steam reforming of methane, pyrolysis of light hydrocarbons, hyddrocracking and delayed coking;

- Based on the own experience of work performed in Russia and Eastern Europe, the HEC coating was applied to furnaces of variuos licensors, designers and manufacturers of furnaces, including: UOP, Technip, Chevron, ABB Lummus, Foster Wheeler (WOOD), Heurtey Petrochem, Kirchner, VNIINeftemash, KEDR-89, Aliter-Axi. Russian furnace designer LLC "RAN COMPLECT" provides for HEC coating in the projects for new furnaces;

- HEC coatings were applied to various types of refractory including chamotte bricks, fire-resistant concrete, soft ceramic fiber;

- The actual affect was evaluated when using as fuel in furnaces liquid fuel, "fatty" in-plant gas, fuel mixtures with natural gas, and in-plant hydrogen-containing gases;

- Almost all the works were accompanied by an assessment of the actual effect obtained AFTER applying HEC coatings, expressed in a reduction of the specific consumption of equivalent fuel in comparison with the periods BEFORE.