No matter what to say, the environment plays a primary role in our lives. This is what we breathe, what we drink and eat, what we hear, see, smell, touch, feel with our skin.

Everyone wants to be healthy and live happily ever after. This is a dream that unites all living organisms on the Planet Earth.

This means that it is a Sacred Task to preserve, improve and beautify the Environment or Nature around us.

Employees of "Green Ray" are proud without false modesty of the contract successfully and timely executed in the EPCM format for the Reconstruction of the Catalytic Cracking Unit with a capacity of 2.1 million tons of raw materials per year in terms of the reconstruction of the Heat Recovery Section (C-400) and new Filter Section for cleaning waste gases of the Regenerator from the catalyst dust.

This project was primarily Environmental-oriented, but the economy in the form of increased steam generation at the Waste Heat Boiler was also part of the Technical Requirements of JSC "LUKOIL Neftochim Burgas".

Compliance with EU requirements for such installations was a requirement of the Republic of Bulgaria, taking into account the resort area of the Refinery in Burgas.

We hope that the result achieved will strengthen the health of local residents of the city of Burgas, the Burgas region, all tourists and guests of Sunny and Hospitable Bulgaria. We do not exclude that the improvement of the environmental situation will affect the cost of real estate in this area of Bulgaria.

In the process of creating the Concept Design, a Technical Solution was developed that has never been used in the world for Catalytic Cracking Units before. The result was recognition and gratitude from local residents, specialists, Management of JSC "LUKOIL Neftochim Burgas" and ecologists of the European Community.

This successfully implemented Solution is THE BEST EUROPEAN PRACTICE for cleaning the Regenerator gases from the FCCU unit from the catalyst dust with the actually achieved degree of dust cleaning up to 10 mg / Nm3 at the current European norm of 40 mg/Nm3 of the catalyst dust content.

Source of information: Letter of 23.06.2017, Ref.No.100-01-3542-23.06.2017

In 2014, AD "LUKOIL Neftekhim Burgas" implemented a Project for the reconstruction of the Heat Recovery and Cleaning System of the P-202 regenerator gases from the catalytic dust at the Catalytic Cracking Unit (FCCU) with a capacity of 2 million tons/year.

During the implementation of the Project, the Waste Heat Boiler was changed on new one with boiler water treatment station, the new gas cleaning system (Filter) from catalyst dust with a system for continuous monitoring of harmful emissions was installed, and the closed system for collecting and transporting captured catalyst dust from the boiler and filter to the separate silo for subsequent unloading was installed.

The scope of the contractor's work of the executed Project included the development of project documentation, equipment delivery, installation, supervision and commissioning.

According to the objective control data of the continuous emission monitoring system, the content of catalyst dust in the waste gases does not exceed 10 mg/Nm3.

After two years of industrial operation, the installed System maintains sustainable and reliable performance parameters for the steam capacity of the waste heat boiler, the efficiency of cleaning the regenerator gases from catalyst dust, and ensures compliance with the requirements of European standards (EU 201/75/EC).

The work was completed in the required time, efficiently and in accordance with the requirements specification

Ilshat Sharafutdinov, Chairman of the Executive Board of JSC "LUKOIL Neftekhim Burgas"

Reduction of catalyst dust emissions at LUKOIL Neftohim Burgas AD

A new waste heat boiler П-401 was built at the Catalytic Cracking unit, and a DAHLMANN filtration system was also installed.

The system is a new generation technology in oil refining and this is one of its first applications within the European Union.

In contrast to the treatment facilities widely used up this moment, allowing to achieve catalyst dust emissions reduction to 20—40 mg/nm3, the new process guarantees 10 mg/nm3, and the analysis done during the test of the installed filter demonstrated results of 0,3 mg/nm3.

The implementation of this project enabled the achievement of major ecological effects:

• Substantial improvement of Catalytic Cracking unit's energy efficiency;

• Improved heat energy savings amounting to 48 th. MWt per year;

• Reduced emissions of greenhouse gases — СО2 to 45 kt/year (cca. 5% of total СО2 emissions of the refinery);

• Reduced catalyst dust emissions to 38 tons/year compared to the legally acceptable quantities.

The introduction of this technology will enable LUKOIL Neftohim Burgas to ensure the production's compliance with the new European regulations planned for enforcement in 2020.

Resource:

hhttps://neftochim.lukoil.com/en/Responsibility/Ecology/

Based on this GR's employees solution, a Patent for invention No.2674967 dated 24.08.2017 "Method for cleaning high-temperature aerosols" was obtained.

This Project was presented at the meeting of the Council of Chief Ecologists in the Spring of 2019 with the award of the 2nd place to the Report:

As a result of the successful implementation of this project, the employees of "Green Ray" prepared a number of presentations and reports presented at various public events. Here are the names of some of them:

"Systems for Cleaning and Heat Utilization from regenerator gases in Catalytic Cracking Units. Best practices."

"Reconstruction of the Heat Recovery Section and Cleaning Section the Regenerator gases at the FCC Unit of the JSC "LUKOIL Neftochim Burgas".

We are ready to answer all your questions about this technical solution and the practical results of its implementation.

Green Ray Ltd. took part in the II-th International Annual Forum-Exhibition "Clean Country" in the technopark of the Skolkovo Innovation Center in March 2021.

Green Ray company is welcoming and supporting National Projects and Programs of Russia, and continues to develop and improve the technology of "dry" non-catalytic purification of industrial gases from harmful substances under the trademark GDryC Sys ® (Gas Dry Cleaning Systems) together with partners.

GDryC Sys ® (Gas Dry Cleaning Systems) - systems of "dry" waste-free cleaning of industrial gases from harmful substances

GDryC Sys conceptually sets the task of avoiding and minimizing the amount of any kind of harmful industrial waste.

The MAX goal is to catch harmful substances from gases as efficiently as possible, to transfer them to a safe form, and upsycling them to obtain useful products from waste with the couse to obtain balance-sheet commodity products of production with a market value.

For dusty gases with a high content of catalyst dust (gases of the regenerator of the FCC catalytic cracking plant), ash (flue gases of boilers and solid fuel stations), coke dust (oil coke calcination plant), cement dust and others, GDryC Sys has a configuration of the following Blocks:

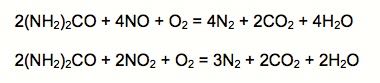

De-NOx

Nitrogen Oxide purification Block;

De-Dust

The Block of gas cleaning from Mechanical Solids;

De-SOx

Sulfur Oxides purification Block.

De-NOx Block

Purification of gases from nitrogen oxides by the technology of selective non-catalytic reduction of nitrogen:

De-Dust Block

Bag House Filters of barrier type with modern filtering materials allow to achieve purification of gases from mechanical particles with a degree of cleaning oup to 10 mg/nm3.

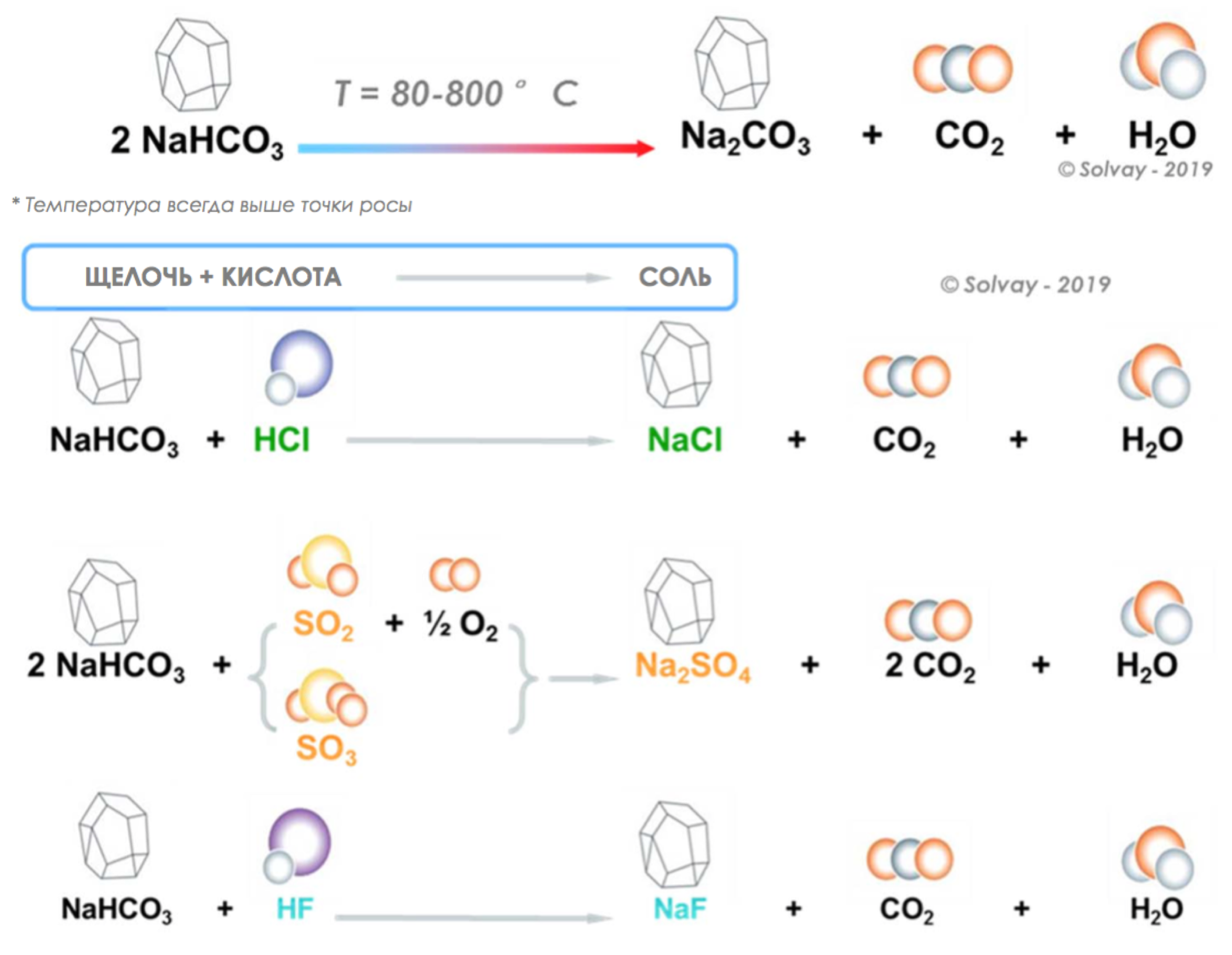

De-SOx Block

Non-catalytic purification of gases using soda sorbents by "dry" injection into the reaction zone of the gas flow in order to obtain chemical reactions converting SOx, HCl, HF, CO2 into sodium-containing compounds:

Advantages of the GDryC Sys ® (Gas Dry Cleaning Systems) :

- High cleaning efficiency;

- Absence of water, liquid media and harmful effluents;

- Minimal harmful impact on the environment;

- No need for catalysts;

- Inexpensive and commercially available reagents;

- The possibility of excluding all types of waste and pollution (air, water, soil) in case of successful upcycling of trapped mechanical particles and chemical reaction products.

The Partners of Green Ray Ltd. are:

Faculty of Chemical and Environmental Engineering

Gubkin Russian State University of Oil and Gas (National Research University)

Download the DFM Sys Brochure GDryC Sys

"Green Ray Ltd" promotes the Technology of increasing the efficiency of fire apparatus by "blackening" the combustion chambers of furnaces in the market of energy-intensive industries.

that aims to reduce the specific consumption of conventional fuel during its efficient combustion, which means to reduce emissions of harmful substances into the atmosphere, including flue greenhouse gases (CO2 and H2O). The Technology is described on the following page of this website:

The Technology of "blackening" the fireboxes of furnaces

The company Green Ray Ltd. together with its partner company Texplore Co.Ltd. decided to jointly promote the Technology of "blackening" fireboxes of furnaces using emisspro® product line on the market of Russia, the CIS and Eastern European countries.

The companies jointly participated in the Annual Congress on Oil Refining and Petrochemistry PRC Russia CIS in St. Petersburg on September 20-21, 2021 and presented samples at their exhibition stand as part of the Congress.

At the end of 2021, emisspro® products were approved for use for their purposes by AXENS.

Further, these products were presented at the V International Conference of JSC "VTI" on Solid Fuels in April 2022 and at the Meeting of the Council of Chief Power Engineers of Oil Refining and Petrochemical Enterprises of Russia and CIS in October 2022. There were presented technologies of environmental orientation - DFM Sys™ and WH @ Cleaning™.